Combining the best of in-house and external expertise

Product design is done in-house with support from best-in-field technological partners.

Our capabilities:

It is no secret that perhaps one of the keys to our success is blending our in-house expertise with the unparalleled skills of external collaborators. Our product design process is meticulously carried out in-house and enhanced by the support and insights from top experts in the field.

Our know-how extends across a diverse range of skills:

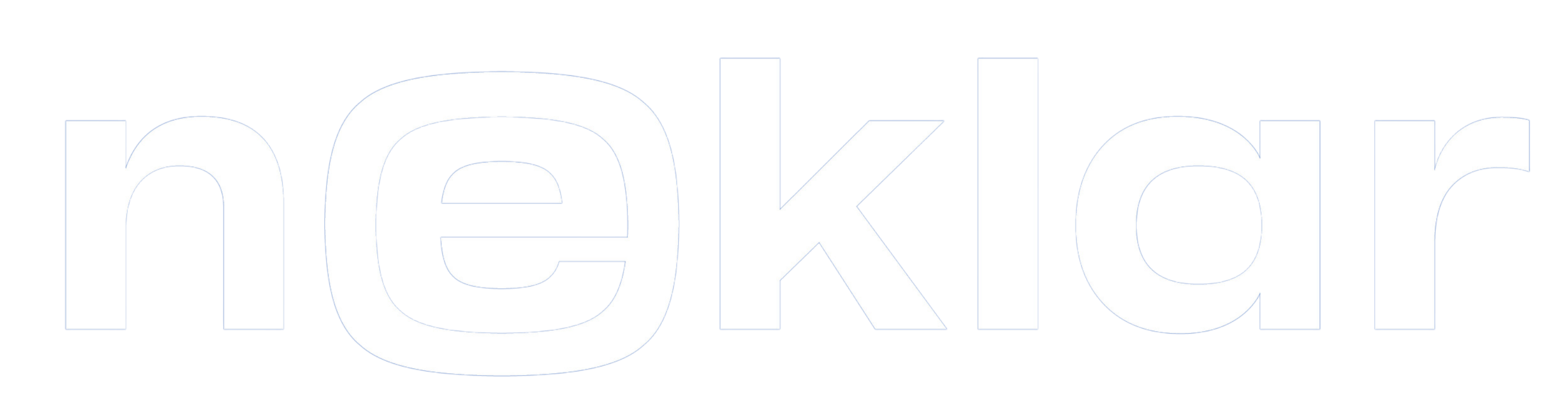

- We are proficient in product design, thanks to our advanced Catia NX software, which allows us to create detailed and precise designs.

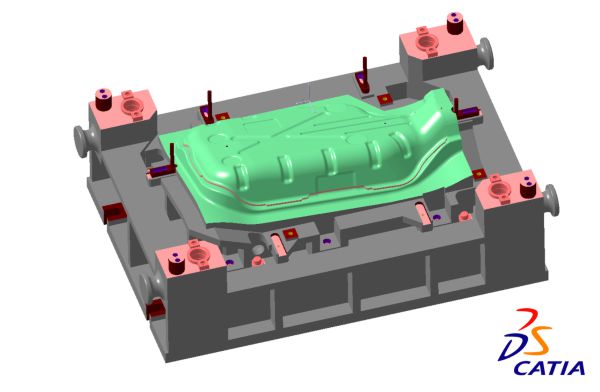

- Our team is highly skilled to conduct comprehensive thermal analyses, these ensure that our products can withstand various temperature conditions without compromising their integrity.

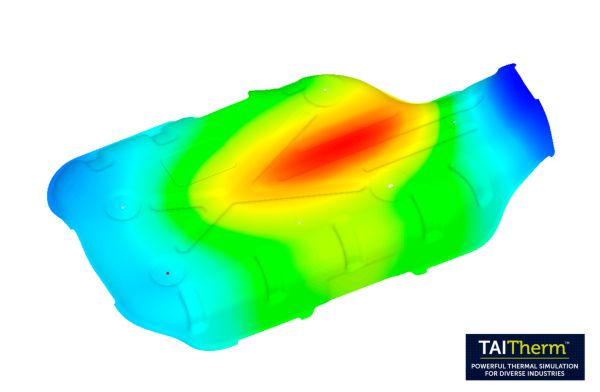

- Regarding mechanical analysis, we excel in both modal frequency analysis and random response analysis. These methods allow us to predict and mitigate any potential issues related to vibrations and structural responses, ensuring the longevity and reliability of our products.

- Additionally, the forming analysis enables us to validate that the product stays within the formability limits of the selected material.

- Through an electromagnetic analysis we are able to gauge the quality of the product throughout its lifespan.

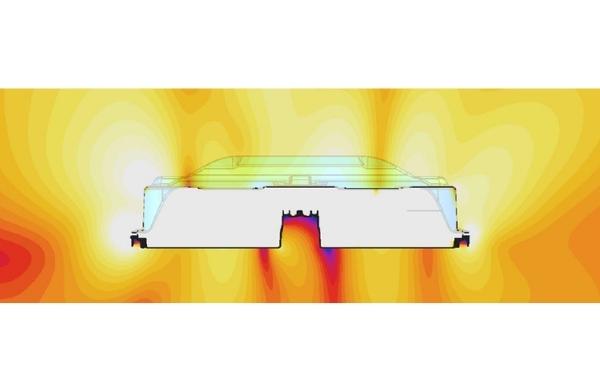

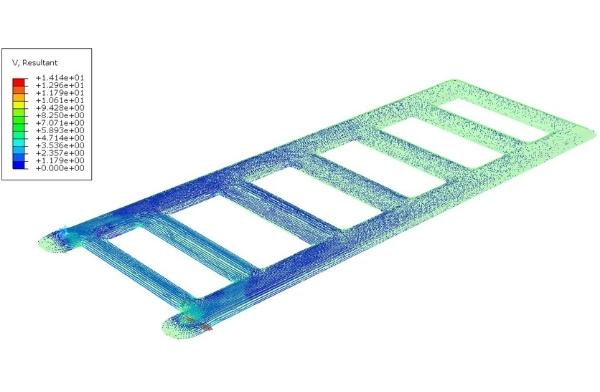

- Lastly, our proficiency in computational fluid dynamics (CFD) allows us to analyze and optimize fluid flows within our products, enhancing their efficiency and performance.

This blend of in-house expertise and external collaboration positions us uniquely in the metal stamping industry. Our approach is not just about producing metal parts; it’s about engineering solutions that are robust, efficient, and tailored to meet the highest quality standards.

Product design using Catia NX

Thermal analysis

Mechanical analysis

Modal frequency analysis

Random response analysis

Forming analysis

Electromagnetic analysis

Computational fluids dynamic

Hands-on testing:

Since 1984 our approach to testing ensures that each product exceeds industry standards thanks to our four key tests: thermal, chemical, mechanical, and acoustic.

- Thermal testing is crucial for assessing how our products behave under various temperature conditions. To carry out this test, we simulate extreme heat and cold to guarantee the stability and durability of our products regardless of the environment conditions. This process is crucial to identify potential thermal degradation or deformation risks.

- Chemical testing is another key step in our quality control. We expose our parts to various chemicals to evaluate their resistance and durability. This process is especially important for products used in harsh chemical environments, ensuring they withstand corrosion, oxidation, and other chemical impacts.

- Mechanical testing is the backbone of our quality assurance. We subject our products to stress, strain, and impact tests to measure their strength and elasticity. This rigorous testing confirms that our products can withstand the physical demands of their intended applications.

- Finally, acoustic testing is conducted to ensure our products meet the noise level standards. This test is fundamental to ensure compliance with industry-specific acoustic requirements and contributing to a more comfortable and safe working environment.

At Neklar, we believe in hands-on testing and our solutions are adapted to new technologies to achieve clean mobility. Our commitment to quality at every stage of product development sets us apart in the metal stamping industry.

Fast prototyping for best results

Neklar uses fast prototyping to optimize series tooling design and product performance. Prototype tools are adapted to specific client needs such as lead time, cost and tool lifetime. This also allows us to use our expertise on materials and processes to ensure the highest quality finishing.

Focusing on innovation

Innovation is one of our main business drivers. We believe in change, development, transformation and progress. Our innovation team is actively generating new ideas and turning them into solutions with the support of our designers.

We are currently very excited working on three granted & consortium projects:

FORMPLANET, on boosting the sheet metal forming industry under the HORIZON 2020 program.

Click here to learn more.

LUBRINTEL, new intelligent lubrication systems for metal processing under the funding of CIEN.

Click here to learn more.